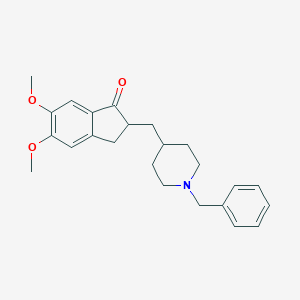

Donepezil

カタログ番号 B133215

分子量: 379.5 g/mol

InChIキー: ADEBPBSSDYVVLD-UHFFFAOYSA-N

注意: 研究専用です。人間または獣医用ではありません。

Patent

US08124783B2

Procedure details

There are many processes as disclosed in the prior arts for producing donepezil of formula 1. U.S. Pat. No. 4,895,841 wherein substituted 1-indanone-2-phosphonate prepared from 2-bromo-5,6-dimethoxyindanone and triethyl phosphite, is treated with 1-benzylpiperidine-4-carboxaldehyde in the presence of a strong base, such as lithium diisopropylamide (LDA), followed by catalytic reduction using palladium on carbon in tetrahydrofuran (40 volumes) to yield donepezil with an overall yield of 50.8%. This process however suffers with few limitations i.e. it employs triphenylphosphonium methoxymethyl chloride, which is expensive and toxic and the overall yield of this process is quite low. (scheme 1).

[Compound]

Name

substituted 1-indanone-2-phosphonate

Quantity

0 (± 1) mol

Type

reactant

Reaction Step One

Name

Yield

50.8%

Identifiers

|

REACTION_CXSMILES

|

Br[CH:2]1[CH2:10][C:9]2[C:4](=[CH:5][C:6]([O:13][CH3:14])=[C:7]([O:11][CH3:12])[CH:8]=2)[C:3]1=[O:15].P(OCC)(OCC)OCC.[CH2:26]([N:33]1[CH2:38][CH2:37][CH:36]([CH:39]=O)[CH2:35][CH2:34]1)[C:27]1[CH:32]=[CH:31][CH:30]=[CH:29][CH:28]=1.C([N-]C(C)C)(C)C.[Li+]>[Pd].O1CCCC1>[CH3:12][O:11][C:7]1[CH:8]=[C:9]2[CH2:10][CH:2]([CH2:39][CH:36]3[CH2:35][CH2:34][N:33]([CH2:26][C:27]4[CH:28]=[CH:29][CH:30]=[CH:31][CH:32]=4)[CH2:38][CH2:37]3)[C:3](=[O:15])[C:4]2=[CH:5][C:6]=1[O:13][CH3:14] |f:3.4|

|

Inputs

Step One

[Compound]

|

Name

|

substituted 1-indanone-2-phosphonate

|

|

Quantity

|

0 (± 1) mol

|

|

Type

|

reactant

|

|

Smiles

|

|

|

Name

|

|

|

Quantity

|

0 (± 1) mol

|

|

Type

|

reactant

|

|

Smiles

|

BrC1C(C2=CC(=C(C=C2C1)OC)OC)=O

|

|

Name

|

|

|

Quantity

|

0 (± 1) mol

|

|

Type

|

reactant

|

|

Smiles

|

P(OCC)(OCC)OCC

|

Step Two

|

Name

|

|

|

Quantity

|

0 (± 1) mol

|

|

Type

|

reactant

|

|

Smiles

|

C(C1=CC=CC=C1)N1CCC(CC1)C=O

|

|

Name

|

|

|

Quantity

|

0 (± 1) mol

|

|

Type

|

reactant

|

|

Smiles

|

C(C)(C)[N-]C(C)C.[Li+]

|

Step Three

|

Name

|

|

|

Quantity

|

0 (± 1) mol

|

|

Type

|

catalyst

|

|

Smiles

|

[Pd]

|

Step Four

|

Name

|

|

|

Quantity

|

0 (± 1) mol

|

|

Type

|

solvent

|

|

Smiles

|

O1CCCC1

|

Conditions

Other

|

Conditions are dynamic

|

1

|

|

Details

|

See reaction.notes.procedure_details.

|

Outcomes

Product

|

Name

|

|

|

Type

|

product

|

|

Smiles

|

COC=1C=C2C(=CC1OC)C(=O)C(C2)CC3CCN(CC3)CC=4C=CC=CC4

|

Measurements

| Type | Value | Analysis |

|---|---|---|

| YIELD: PERCENTYIELD | 50.8% |

Source

|

Source

|

Open Reaction Database (ORD) |

|

Description

|

The Open Reaction Database (ORD) is an open-access schema and infrastructure for structuring and sharing organic reaction data, including a centralized data repository. The ORD schema supports conventional and emerging technologies, from benchtop reactions to automated high-throughput experiments and flow chemistry. Our vision is that a consistent data representation and infrastructure to support data sharing will enable downstream applications that will greatly improve the state of the art with respect to computer-aided synthesis planning, reaction prediction, and other predictive chemistry tasks. |

Patent

US08124783B2

Procedure details

There are many processes as disclosed in the prior arts for producing donepezil of formula 1. U.S. Pat. No. 4,895,841 wherein substituted 1-indanone-2-phosphonate prepared from 2-bromo-5,6-dimethoxyindanone and triethyl phosphite, is treated with 1-benzylpiperidine-4-carboxaldehyde in the presence of a strong base, such as lithium diisopropylamide (LDA), followed by catalytic reduction using palladium on carbon in tetrahydrofuran (40 volumes) to yield donepezil with an overall yield of 50.8%. This process however suffers with few limitations i.e. it employs triphenylphosphonium methoxymethyl chloride, which is expensive and toxic and the overall yield of this process is quite low. (scheme 1).

[Compound]

Name

substituted 1-indanone-2-phosphonate

Quantity

0 (± 1) mol

Type

reactant

Reaction Step One

Name

Yield

50.8%

Identifiers

|

REACTION_CXSMILES

|

Br[CH:2]1[CH2:10][C:9]2[C:4](=[CH:5][C:6]([O:13][CH3:14])=[C:7]([O:11][CH3:12])[CH:8]=2)[C:3]1=[O:15].P(OCC)(OCC)OCC.[CH2:26]([N:33]1[CH2:38][CH2:37][CH:36]([CH:39]=O)[CH2:35][CH2:34]1)[C:27]1[CH:32]=[CH:31][CH:30]=[CH:29][CH:28]=1.C([N-]C(C)C)(C)C.[Li+]>[Pd].O1CCCC1>[CH3:12][O:11][C:7]1[CH:8]=[C:9]2[CH2:10][CH:2]([CH2:39][CH:36]3[CH2:35][CH2:34][N:33]([CH2:26][C:27]4[CH:28]=[CH:29][CH:30]=[CH:31][CH:32]=4)[CH2:38][CH2:37]3)[C:3](=[O:15])[C:4]2=[CH:5][C:6]=1[O:13][CH3:14] |f:3.4|

|

Inputs

Step One

[Compound]

|

Name

|

substituted 1-indanone-2-phosphonate

|

|

Quantity

|

0 (± 1) mol

|

|

Type

|

reactant

|

|

Smiles

|

|

|

Name

|

|

|

Quantity

|

0 (± 1) mol

|

|

Type

|

reactant

|

|

Smiles

|

BrC1C(C2=CC(=C(C=C2C1)OC)OC)=O

|

|

Name

|

|

|

Quantity

|

0 (± 1) mol

|

|

Type

|

reactant

|

|

Smiles

|

P(OCC)(OCC)OCC

|

Step Two

|

Name

|

|

|

Quantity

|

0 (± 1) mol

|

|

Type

|

reactant

|

|

Smiles

|

C(C1=CC=CC=C1)N1CCC(CC1)C=O

|

|

Name

|

|

|

Quantity

|

0 (± 1) mol

|

|

Type

|

reactant

|

|

Smiles

|

C(C)(C)[N-]C(C)C.[Li+]

|

Step Three

|

Name

|

|

|

Quantity

|

0 (± 1) mol

|

|

Type

|

catalyst

|

|

Smiles

|

[Pd]

|

Step Four

|

Name

|

|

|

Quantity

|

0 (± 1) mol

|

|

Type

|

solvent

|

|

Smiles

|

O1CCCC1

|

Conditions

Other

|

Conditions are dynamic

|

1

|

|

Details

|

See reaction.notes.procedure_details.

|

Outcomes

Product

|

Name

|

|

|

Type

|

product

|

|

Smiles

|

COC=1C=C2C(=CC1OC)C(=O)C(C2)CC3CCN(CC3)CC=4C=CC=CC4

|

Measurements

| Type | Value | Analysis |

|---|---|---|

| YIELD: PERCENTYIELD | 50.8% |

Source

|

Source

|

Open Reaction Database (ORD) |

|

Description

|

The Open Reaction Database (ORD) is an open-access schema and infrastructure for structuring and sharing organic reaction data, including a centralized data repository. The ORD schema supports conventional and emerging technologies, from benchtop reactions to automated high-throughput experiments and flow chemistry. Our vision is that a consistent data representation and infrastructure to support data sharing will enable downstream applications that will greatly improve the state of the art with respect to computer-aided synthesis planning, reaction prediction, and other predictive chemistry tasks. |